Ground Vibration Monitoring Mission Statement:

The Ground Vibration Monitoring website seeks to answer the most common questions pertaining to ground vibration monitoring in order to help the user determine…

What is ground vibration monitoring?

Who uses ground vibration monitoring?

How do ground vibration monitors work?

Where can I rent ground vibration monitors?

In addition, it provides information pertaining to recommended instruments, basic monitor setup, industry standards, and a page of posts containing frequently ask questions and troubleshooting.

What is ground vibration monitoring?

Ground vibration monitoring is the process of measuring and recording the movements in the ground using a seismograph. As vibration occurs at a source, a seismic wave travels causing soil and rock particles to move back and forth over very small distances. This is known as particle velocity. The vibration monitor measures the Peak Particle Velocity: the maximum speed of a particular particle as it oscillates about a point of equilibrium, caused by the traveling seismic wave. By measuring the Peak Particle Velocity in inches per second, operators indicate whether damage is likely to occur to surrounding structures.

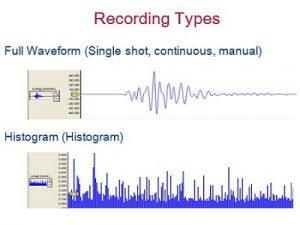

Unlike large, permanently mounted seismographs that measure earthquakes or other geologic events, ground vibration monitors are small and portable with the ability for programming specific parameters. Therefore, an operator programs the unit to specific parameters that only record during a given time period or only trigger a recording once a certain criterion occurs.

Generally, these monitors record man-made vibrations as opposed to natural seismic occurrences. To learn more about monitoring natural seismic activity, please visit the U.S. Geological Society Earthquake Monitoring page.

Who uses ground vibration monitoring?

Ground vibration monitoring records vibrations caused by traffic and construction projects as well as quarry and mining operations. Engineers and construction companies usually assess their ground vibration to make certain that machinery and construction work does not cross a threshold, causing structural damage to neighboring buildings and infrastructure. Likewise, quarry and mine operators monitor the vibration caused by blasts, compaction methods, and heavy machinery/equipment. In some instances, they use the monitors to measure the damaging air overpressure caused by a blast and fine tune their blasting techniques.

All ground vibration is of some concern. Most heavy construction projects centered in urban areas and industries involved in blasting require monitoring the ground vibration that they cause. However, that doesn’t mean that homeowners or businesses near these sites should not contract an experienced company to perform ground vibration monitoring. The ability to prove that ground vibration from an outside source caused or did not cause damage protects those that pay to conduct a survey. Ultimately, the reports from vibration monitors prove helpful in demonstrating whether vibration is great enough to cause concern or not.

How do ground vibration monitors work?

Ground vibration monitors use a transducer, also called a geophone, to measure vibrations. To properly measure these vibrations, securely couple the geophone to either the ground or a structure. This ensures that the geophones sense all the energy in the ground. Inside the geophone, a spring-mounted, magnetic mass moves within a wire coil when the ground vibrates. This produces an electrical signal proportional to the ground vibration velocity that the monitor records.

Ground vibration monitoring measures three types of ground vibrations.

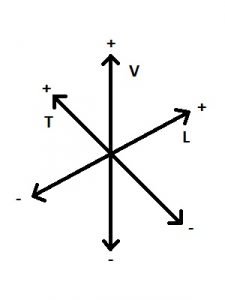

The ground vibration monitor’s transducer is a triaxial geophone. This means it measures vibration on three planes. Transverse ground vibrations cause particles to move in a side to side motion. Vertical ground vibrations cause particles to move in an up and down motion. Longitudinal ground vibrations cause particles to move in a back and forth motion progressing outward from the source.

To receive good results and properly distinguish transverse vs vertical vs longitudinal vibrations, orientate the geophone correctly. The arrow on the geophone must be visible; otherwise, the geophone is upside-down. Point the arrow on the top of the geophone towards the seismic source. Make certain the geophone is as level as possible. Finally, fasten the geophone securely to the ground or structure. Most geophones come with spikes that stick into the ground. If the ground or surface does not permit spikes, the unscrew the spikes and the couple the geophone to the surface by placing a heavy sandbag over it.

Do ground vibration monitors measure anything else?

Because monitors often record blasts in the quarry and mining industries, microphones are sometimes used to measure air pressure. This damaging air pressure is commonly referred to as an “air blast”. By measuring air pressures, these industries determine the effects of the air blast energy on structures. The monitors connect to two different types of microphones: Linear “L” microphones or “A” weighted microphones. Predominantly, operators use Linear “L” microphones to measure the effect of low frequency air pressure on buildings whereas “A” weighted microphones measure noise levels people consider an annoyance because it’s a scale similar to the human ear.

Where can I rent ground vibration monitors?

Several environmental equipment or geophysical instrument companies rent ground vibration monitors. The Ground Vibration Monitoring website recommends K.D. Jones Instruments.

K. D. Jones Instruments rents Instantel Minimate Plus and Blastmate III units for reasonable rates. These ground vibration monitoring units arrive fully charged as well as factory calibrated. Generally, factory calibration occurs once a year for each unit. Moreover, K.D. Jones Instruments checks every unit for functionality before sending an item to a customer. All in all, over 25 units are available and ready to rent. Typically, vibration monitors are sent with geophones with a 2 to 250 Hz range. Moreover, they conform to use with the ISEE (International Society Of Explosive Engineers) standard.

In addition to the vibration monitor, accessories such as DIN geophones, waterproof geophones, extension leads, alarm boxes, field printers, uninterruptible power supplies, or linear microphones are available upon special request.

Find help with Minimate Plus and Blastmate III setup at VibrationMonitoringCourse.com.

Ground Vibration Monitoring Recording

Connecting an Instantel Ground Vibration Monitor to Blastware